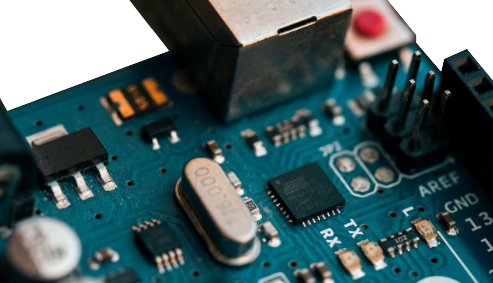

PCBA

Placement Capability: 72,000/ 39,000/ 28,000 CPH (0.05~1.3sec/CHIP)

Target Components: 01005~55 x 55mm

Placement Accuracy: ± 0.05mm/CHIP

Repeatability Accuracy: ± 0.03mm/ CHIP

Product Capacity: 15 million / year

SMT process flow

preparation before production—> solder paste printing/red glue—> patch—> first article inspection—> pre-furnace inspection—> reflow soldering—> AOI inspection—> QC visual inspection—> semi-finished product delivery

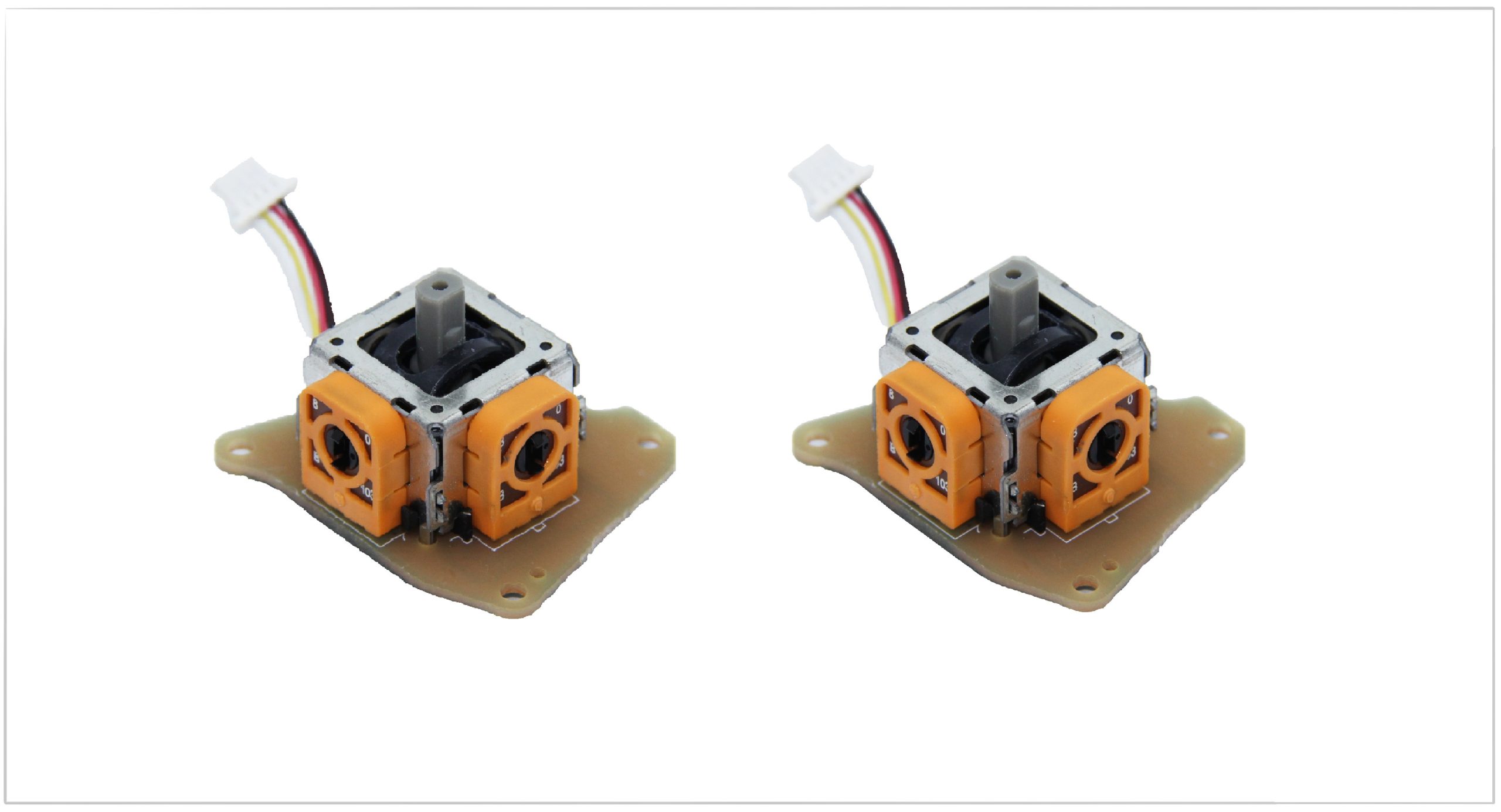

Our SMT products cover many fields for many major customers and meet international standards.

The smallest SMT component size can reach 0201

Able to provide 0.6mm*0.3mm~50mm*50mm QFP

0.15mm gap ±0.05 accuracy

Main applications include:

1. Smart home (wireless headset, smart toothbrush)

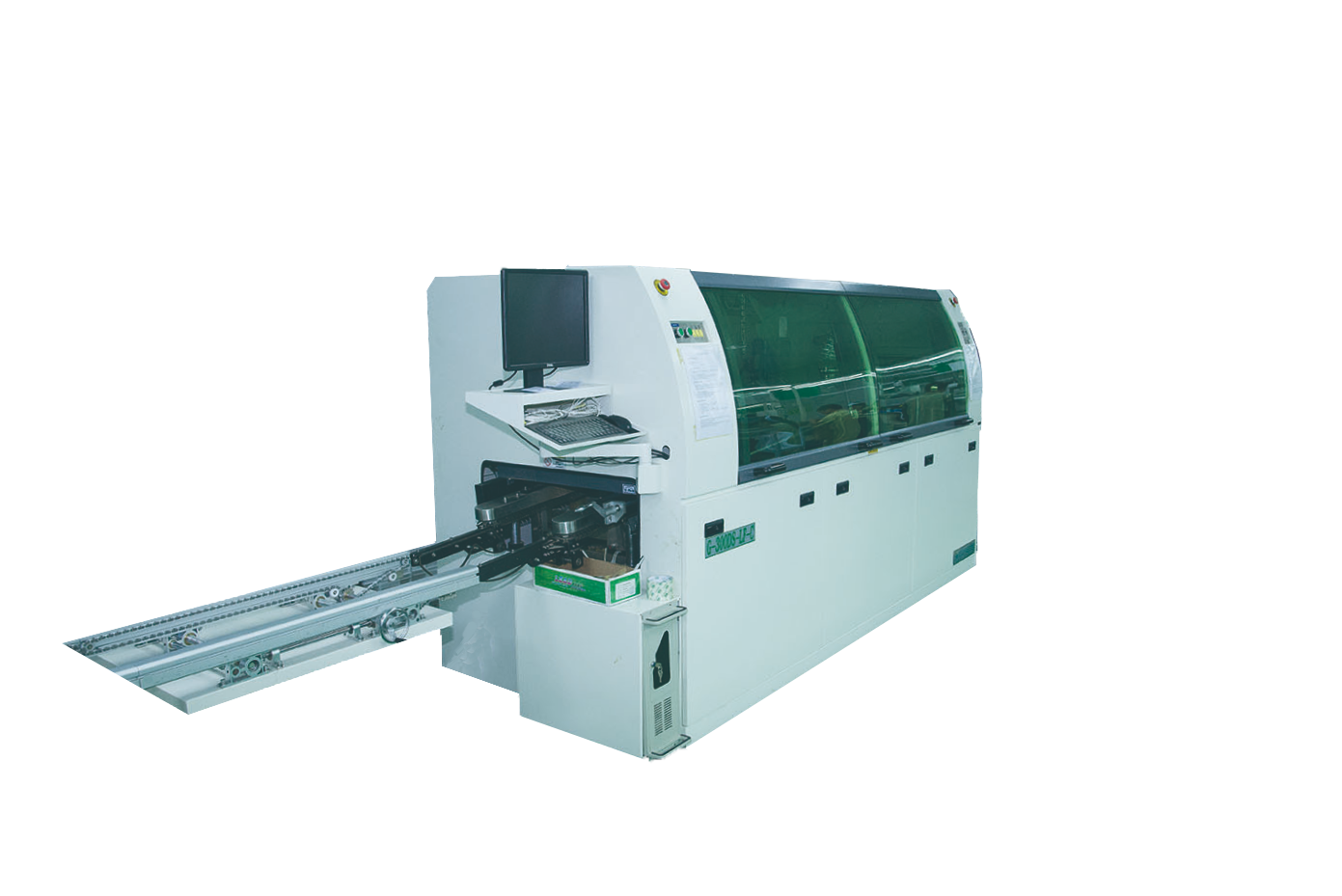

Wave Soldering: Domestic

Capacity: 15 million/year

Power: 90KW Furnace

Temperature Range: 240~300°C

Maximum Card Size: 508*505 mm

Wave soldering process—

PCB board plug-in—>wave soldering furnace—> PCBA height inspection—>Sub-board inspection—-> Sub-board inspection—-> Soldering wire—-> Soldering wire inspection—-> Comprehensive inspection

Our SMT products cover many fields for many major customers and meet international standards.

Main applications include:

- Automotive electronics

(power system, lighting system, sensor)

- Application computer

(computer motherboard)