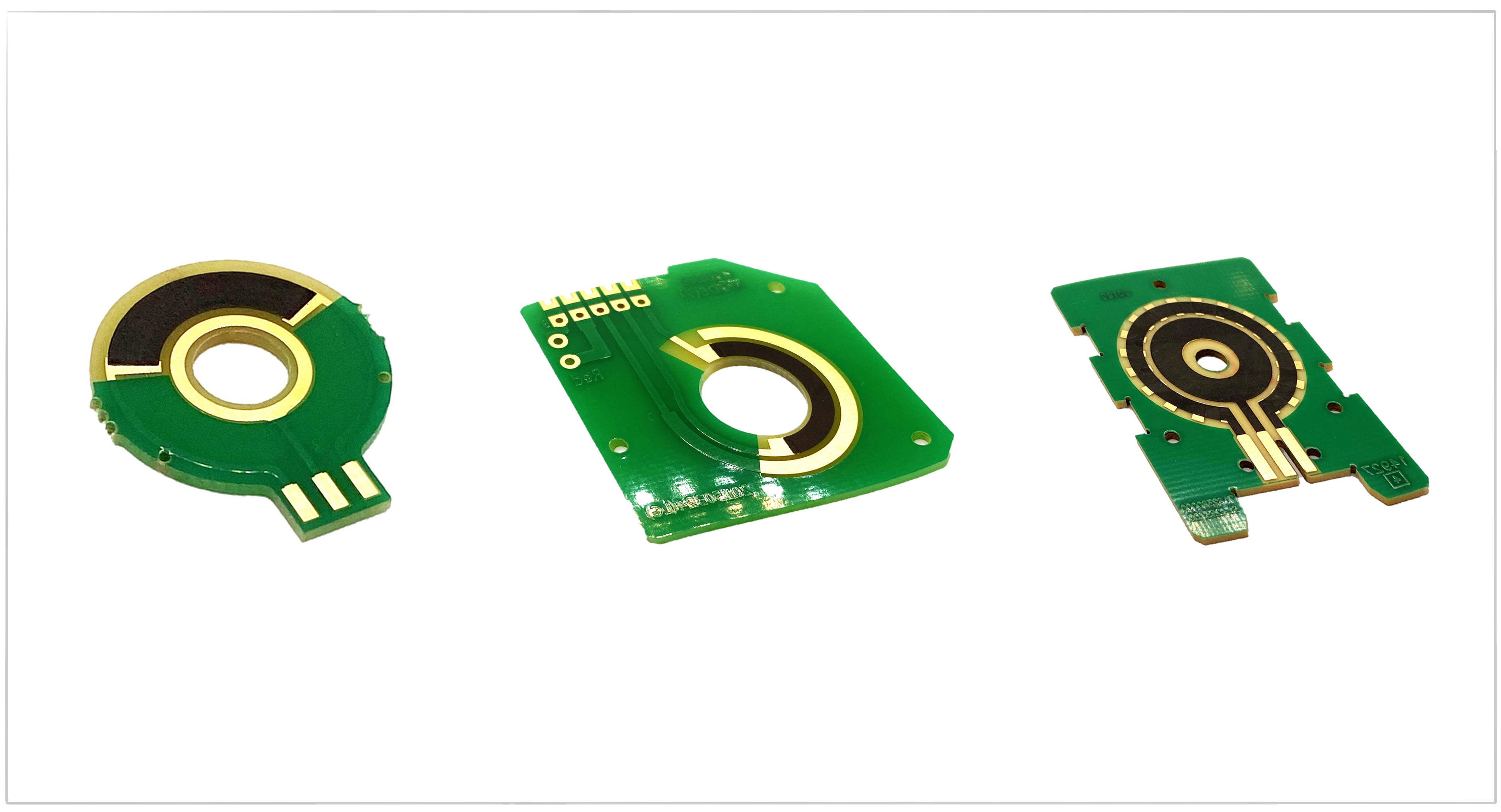

Carbon Printing

1.The technology allows minimum line width of 0.1mm.

2.The machine is equipped with CCD automatic positioning, and the production capacity is 250PNL per hour.

3.Standard product size is within 350mm x 350mm.

4.Customized service and size are also available.

5.Annual production capacity: 30 million PCS/year.

PCB Process Flow

Acid cleaning—> AG Printing—> Semi-drying—> B1 Printing—> Semi-

drying—> B1 Printing—> Semi-drying—> Total Drying—> Blue Glue

Printing—> Drying

Our company can do PCB thick film printing according to customer requirements, the full resistance range is from 1KΩ~3MΩ, the allowable deviation value is ±10%~±30%, and the service life is more than 1 million times.

Main applications include:

1.Automobile

(air conditioning damper sensor, wiper, dimmer, car instrument accessories, rearview mirror accessories, car seat sensor, car steering wheel accessories.)

2.Smart home appliances

(smart sofas, coffee machines, washing machines, printers, power tools.)

1.The technology allows minimum line width of 0.1mm.

2.The machine is equipped with CCD automatic positioning, and theproduction capacity is 250PNL per hour.

3.Standard product size is within 350mm x 350mm.

4.Customized service and size are also available.

5.Annual production capacity: 30 million PCS/year.

ML process flow

dust removal—> AG printing—> semi-drying—> dust removal—> OC

printing—> semi-drying—> dust removal—> B1 printing—> semi-drying—> dust removal—> R printing—> drying

Our FPC (Mylar) products are thin and light, and design changes can be made according to customer requirements. Moreover, it is resistant to high and low temperature (-30~70°C), stable chemical change, high reliability, and the pressing operation life can reach 5 million times.

Main applications include:

1.Game console application(inner soft board of Play Station controller)

2.Application of special medical products(blood glucose test paper for measuring blood glucose value)

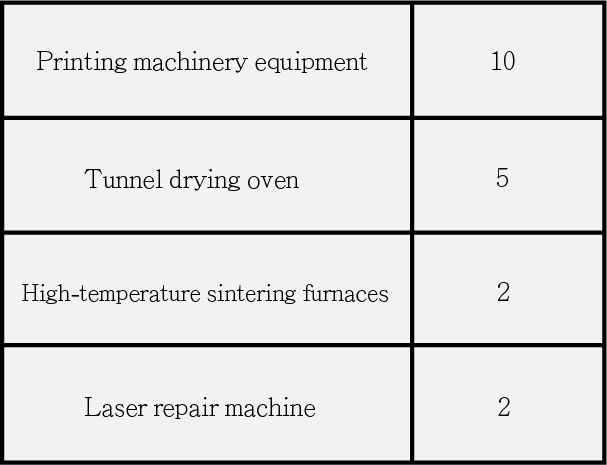

1.CCD automatic precision printing machine

2.Maximum printing size: 150 x 150mm

3.Mesh distance from surface: 0~5 mm

4.Platform positioning accuracy: ≤ 0.01mm

5.Ink layer thickness deviation: ≤ 0.002mm

6.Overprinting accuracy: ≤ 0.02mm

7.Maximum printing capacity: 600 times/H

Ceramic process flow

Pre-printing preparation—> conductor printing—> first article

confirmation—> high temperature sintering—> resistance printing—>

first article confirmation—> high temperature sintering—> protective

layer printing—> first article confirmation—> high temperature Sintering

—> resistance value, appearance inspection —> packaging and storage

The working range of our ceramic products is resistant to high and low temperature (-40~125°C), with strong conductor adhesion, good wear resistance, and the life span of up to 1 million times.

Main applications include:

1.Automotive ceramic thick film circuit (automotive throttle sensor, automotive oil level sensor, electronic igniter, etc.)

2.Power tools

(AC speed control switch)